Swiss Screw Machining Services

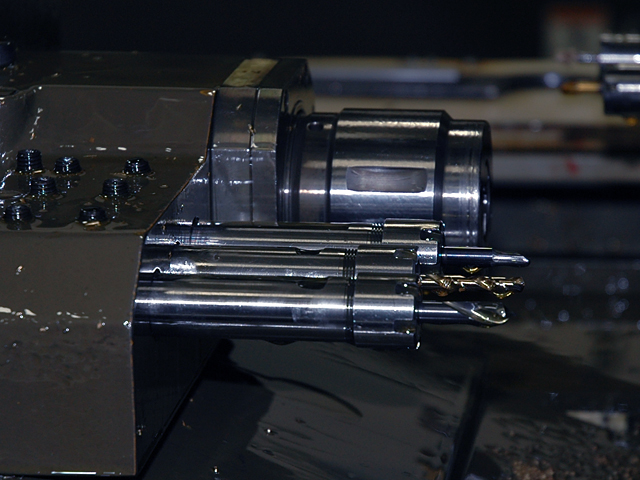

Swiss type machines are versatile, and with a wide variety of attachments can produce most parts complete making secondary operations unnecessary. What sets a Swiss screw machine apart from other turning equipment is the ability to operate multiple spindles to produce a more complex part more efficiently. Once programmed and set-up, the machine requires minimal operator attendance, with the use of automatic bar loaders for our higher production jobs.

The raw bar stock material ranging from sizes up to 1-1/4 inch diameter turns much as it would in a lathe to provide superior finishes on tight tolerances. The material is then fed through a guide bushing, which is usually made of carbide. The bushing is adjusted so that the material can slide through it, but tight enough to keep the material from flexing away from the cutting tool. The guide bushing allows Swiss-type screw machines to hold very tight tolerances (+/- .0001″) over long lengths in relation to part diameter.

For example, if you needed to turn a .100″ diameter over a 3″ length, a Swiss-type screw machine is the only way to do this. On a conventional lathe the material would bend away from the cutting tool. There are many things that make a Swiss unique and possibly the best fit for your part to produce the highest quality and most competitively priced part.

Why use Yampa Precision Swiss machines to make your parts? Our exceptional machinists operating these machines have worked specifically on these types of machines and have a minimum of 10 years of experience. We are your solution for your turned parts for high to low volume.

Some examples of parts our Swiss machines make are Bushings, Nuts, Bolts, Washers, Pins, Spacers, Screws, Valves, Plugs, Extensions and much more.

Swiss Screw Equipment:

- 2 - CITIZEN L32 SWISS SCREW MACHINES

- 5 - CITIZEN L16 SWISS SCREW MACHINES

- 5 - CITIZEN L20 SWISS SCREW MACHINES

- 1 - CITIZEN B12 SWISS SCREW MACHINE

- 4 - CITIZEN M-20 SWISS SCREW MACHINES

- 4 - GANESH CYCLONE-32 CS MACHINES

- 1 - NAKAMURA TOME WT-150

Click here to work with Yampa Precision for your next project. Or call us at 928-772-6616.